At YWX, we offer various advanced molding services, including 2K with ROTATION TABLE, 2K with SPIN STACK turning, and 2K with transfer by robot. Our 2K molding services allow for the creation of complex parts with different materials and colors. With ROTATION TABLE and SPIN STACK turning, we can produce high-quality parts with intricate shapes and designs. Our transfer by robot service enables efficient and precise part transfer, reducing the risk of defects and ensuring consistent quality. With our advanced molding capabilities, we can provide customized solutions to meet your unique production needs.

YWX offers the advanced 2K molding technology with ROTATION TABLE. This technology, which is more mature compared to traditional over-molding techniques, allows for simultaneous injection of two colors. It offers high efficiency and stability, making it suitable for a wide range of products.

1.Inject part #1

2.Rotate the core side 180° vertically

3.In the next cycle, inject part #2 and repeat the process with part #1 again.

With our 2K molding technology and ROTATION TABLE, we can provide precise and reliable manufacturing solutions for your multi-color and multi-material product needs.

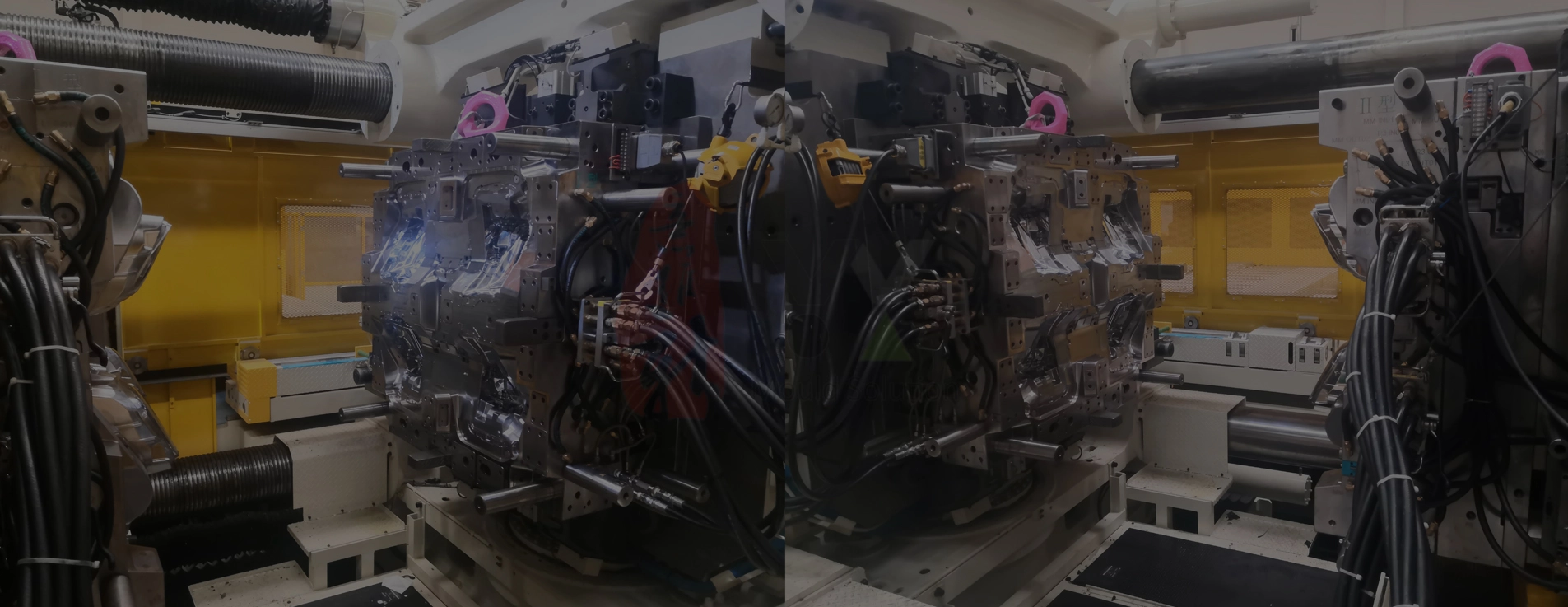

YWX offers advanced 2K molding technology with SPIN STACK turning, which provides several advantages over traditional molding techniques.

1. Production can be done in the same machine with double the number of cavities compared to normal molds, which increases production efficiency.

2. Smaller machine size, lower power consumption, and lower investment in equipment and molds.

3. Faster molding cycle time.

4. Mold rotates on a horizontal turntable, which is more stable than vertical rotation and has no inclination, increasing the lifespan of the mold, especially for large molds.

Here's how the process works:

1. Inject part #1 at the fixed side.

2. The two moving sides rotate 180°.

3. Inject part #2 at the moving side.

With our advanced 2K molding technology and SPIN STACK turning, we can provide efficient and cost-effective solutions for your multi-color and multi-material product needs.

YWX offers advanced 2K molding technology with transfer by robot, which provides several advantages over traditional molding techniques.

Here are some benefits of using 2K with transfer by robot:

1. The use of a robot arm to switch the molding part instead of a rotary table method can help save investment costs in equipment.

2. This technique is commonly applied to simple products and products with metal inserts.

1. Inject part #1.

2. Transfer part #1 to the second molding position using a robot arm.

3. In the next cycle, inject part #2 and repeat the process with part #1 again.

With our advanced 2K molding technology and transfer by robot, we can provide efficient and cost-effective solutions for your multi-color and multi-material product needs.

YWX offers advanced RHCM (Rapid Heat Cycle Molding) technology, which rapidly changes the temperature of the mold during the injection process. This technique not only eliminates welding lines on the surface but also improves the product's gloss rate and mold transferability.

RHCM or rapid heat cool molding is an advanced custom injection molding technology that utilizes rapid mold temperature changes. The process involves heating the mold surface to a point that exceeds the polymer's glass transition temperature and then immediately cooling the mold after the mold cavity fills up. This technique is used to enhance the surface quality of a plastic part while keeping the cycle time as short as possible.

YWX has extensive experience in High Gloss/Welding Line-free Injection Molding with RHCM process. When the molds are matched in the injection machine, high-temperature water is injected to raise the mold temperature to the set value, and then plastic is injected into the cavity.

Our RHCM technology enables us to provide high-quality plastic parts with excellent surface gloss and no welding lines. We're committed to providing customized solutions to meet your unique product needs.