Our Spin Stack Mold Design service offers multi-layered, high-precision molding solutions. This innovative approach allows for increased productivity and design flexibility, ensuring optimal results.

Spin stack mold design allows for simultaneous molding of multiple parts, resulting in higher production output and increased efficiency.

By producing multiple parts in a single molding cycle, spin stack mold design reduces production costs, including material costs, labor costs, and machine time.

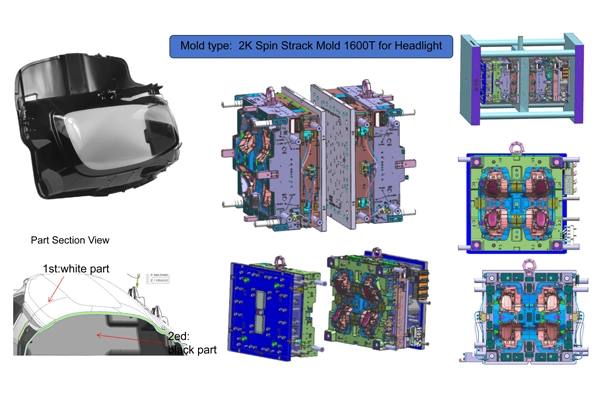

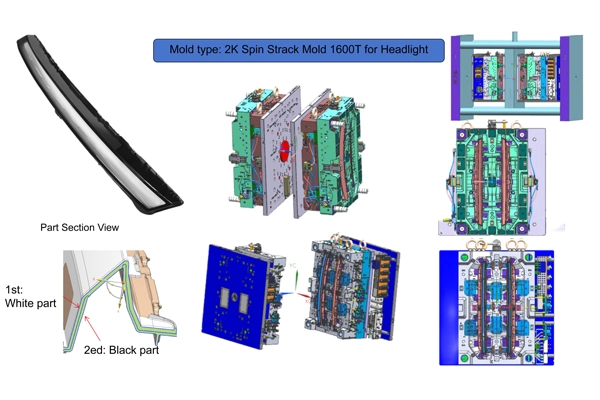

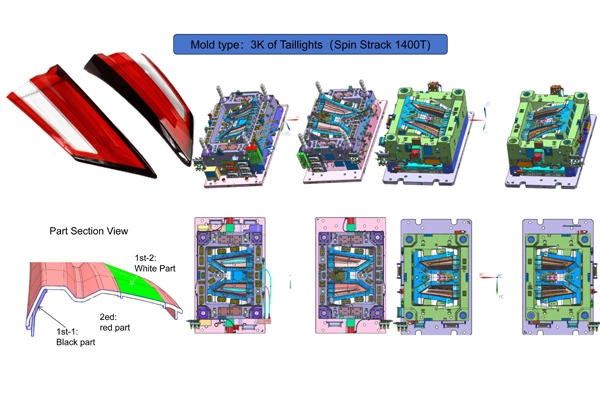

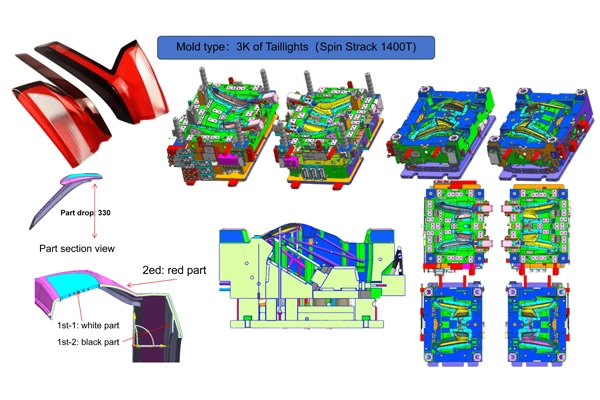

Spin stack mold design offers flexibility in part design, allowing for the production of complex geometries, undercuts, and multi-component parts.

Spin stack mold design reduces cycle time by eliminating the need for separate molding cycles for each part, resulting in faster production and improved overall productivity.

Spin stack mold design ensures consistent part quality and dimensional accuracy, minimizing variations between individual parts.

Spin stack mold design enables the molding of multi-material or multi-color parts in a single molding cycle, expanding design possibilities and enhancing product aesthetics.

Spin stack mold design can integrate multiple components into a single part, reducing the need for assembly and secondary operations, improving efficiency, and reducing costs.

Spin stack mold design allows for the integration of inserts, threads, or other functional features directly into the molded parts, eliminating the need for additional assembly steps.

Spin stack mold design reduces the footprint required for molding multiple parts, optimizing space utilization in the manufacturing facility.

Spin stack mold design is suitable for both low-volume and high-volume production, offering scalability to meet different production requirements.

Spin stack mold design minimizes material waste by utilizing the available space in the mold efficiently, resulting in cost savings and environmental benefits.

Spin stack mold design allows for efficient cooling of the mold, ensuring consistent part quality and reducing cycle time.

Spin stack mold design is typically designed for easy maintenance, allowing for quick mold changes and minimizing downtime during production.

Spin stack mold design can be easily integrated with automation systems, further enhancing productivity and reducing labor requirements.

Spin Stack Mold Design involves a multi-layered molding process that allows for the production of complex parts. It offers increased productivity and design flexibility, making it ideal for high-volume production.