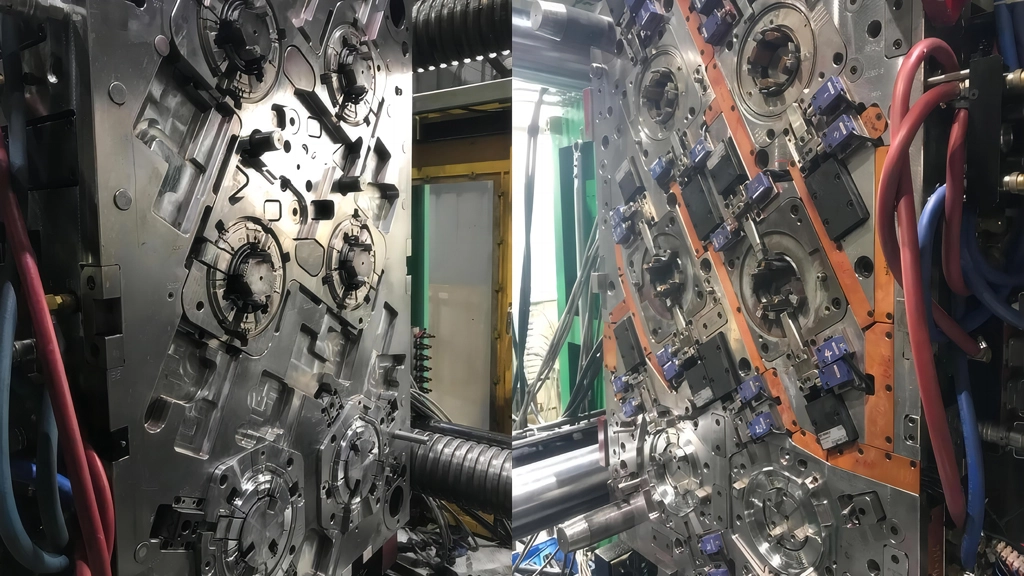

YWX, the plastic injection molding manufacturer specialize in Plastic Injection Molding, a cost-effective method for mass production of high-quality plastic parts. Our advanced technology ensures precision and consistency in every piece.

With 3 sets 2K machines and RHCM in house, and with our leading 2K & rapid heating cooling technology, we are able to manufacture different types of 2K:

2K SPIN STACK molding

2K with rotary table

2K by transfer with robot

RHCM

Plastic injection molding can produce a wide range of complex shapes and sizes, making it suitable for various industries and applications.

Injection molding allows for the production of intricate and precise parts with tight dimensional tolerances.

Plastic injection molding can process a wide variety of thermoplastic materials, including ABS, polypropylene, polycarbonate, nylon, and more, offering a range of material properties and characteristics.

Injection molding ensures consistent and repeatable part production, maintaining the same quality and characteristics throughout the manufacturing process.

Injection molding enables high-volume production with short cycle times, resulting in efficient and cost-effective manufacturing.

Injection molding offers design flexibility, allowing for the production of complex geometries, undercuts, and intricate details.

Injection molding can be a cost-effective solution for high-volume production due to its efficiency, repeatability, and reduced labor costs compared to other manufacturing methods.

Injection molding can achieve various surface finishes, including smooth, textured, matte, or glossy, depending on the mold and process parameters.

Injection molding allows for overmolding, which involves encapsulating or bonding plastic to other materials, such as metals or elastomers, to create multi-material components.

Injection molding can integrate multiple components into a single part, reducing the need for assembly and joining operations, improving efficiency and reducing costs.

Plastic injection molding can produce parts with a wide range of material properties, including flexibility, strength, impact resistance, chemical resistance, and more.

Injection molding is suitable for both low-volume and high-volume production, offering scalability to meet different production requirements.

Injection molding generates less material waste compared to other manufacturing methods, making it a more environmentally friendly process. Additionally, many thermoplastics used in injection molding are recyclable.

Plastic Injection Molding is a manufacturing process where molten plastic is injected into a mold to create parts. It’s a cost-effective method for mass production of high-quality plastic parts with precision and consistency.