Precision, Efficiency, and Quality

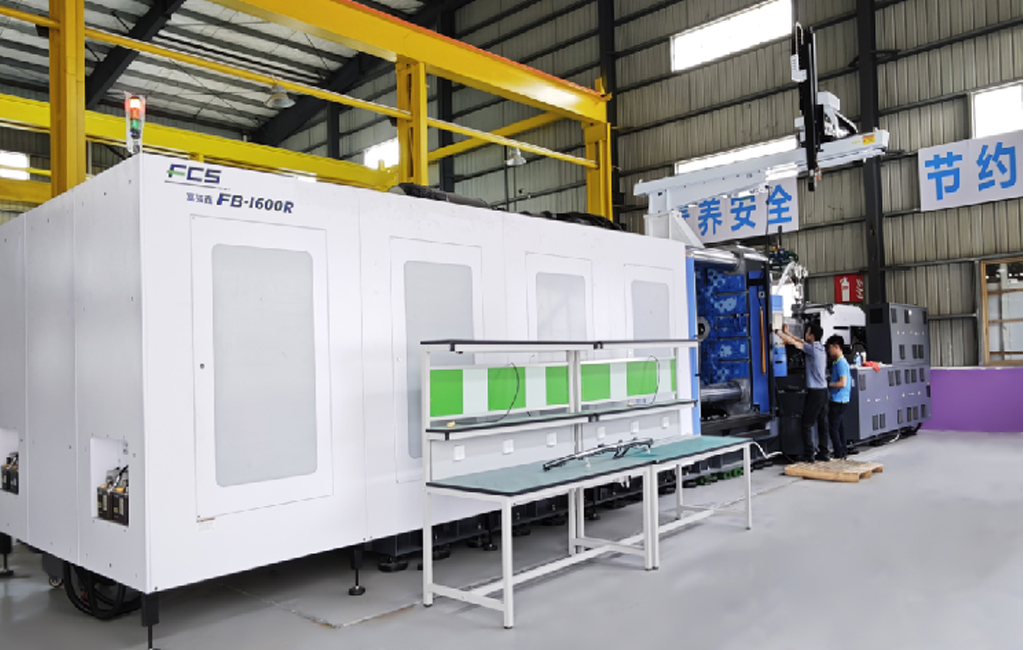

YWX injection molding services ensure the precise and efficient manufacturing of high-quality plastic parts. With modern technology and thorough attention to detail, YWX, an injection molding company in China, provides superior injection molding services that fit our customers' specific needs.

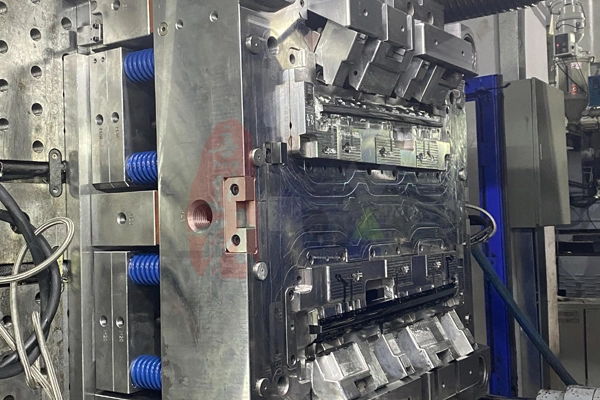

Our YWX molding technology includes over-molding, vertical molding, in-mold labeling (IML), insert molding, 2K/3K molding, 2K SPIN Stack mold injection molding, and gas-assisted molding. YWX, one of China's leading custom injection molding businesses, can provide injection molding services for your projects.

1900T (2K) 1 SET

1650T (2K & 3K) 1 SET

1250T (2K ) 1 SET

900T (2K) 1 SET

600T (2K) 1 SET

Injection molding is a highly versatile manufacturing process used across numerous industries due to its ability to produce complex, high-precision parts with efficiency and cost-effectiveness.

1. Automotive Industry

Injection molding is widely used for manufacturing automotive components such as dashboards, bumpers, door panels, and interior trim. The injection molding process ensures durability, lightweight structures, and high precision in vehicle parts.

2. Electronics & Electrical Industry

Injection molding plays a crucial role in producing electronic enclosures, connectors, and insulating components. The process allows for the integration of intricate designs while ensuring product safety and durability.

3. Medical & Healthcare Sector

Medical device manufacturing benefits from injection molding for producing syringes, surgical instruments, IV components, and implantable devices. The process enables the use of biocompatible materials and ensures strict hygiene standards.

4. Agriculture & Farming

Injection molding is widely used in agriculture for producing durable and weather-resistant components such as irrigation system parts, greenhouse trays, seedling pots, and livestock feeding equipment. The Injection molding process ensures precision, cost-efficiency, and the ability to withstand harsh environmental conditions, making it essential for modern agricultural practices.

Wall thickness: Optimal thickness range for easy molding and part strength

Draft angles: Recommended angles for easy ejection and minimal damage

Gate location: Placement considerations for part appearance and strength

Parting lines: Designing for minimal parting line visibility and impact on function

Undercuts: Minimizing undercuts or designing for easy release with slides or lifters

Material selection: Choosing the right material based on part requirements and properties

Tolerances: Setting realistic tolerances for part dimensions and features

Surface finish: Designing for desired surface finish and texture

Tooling considerations: Designing for easy tooling making production and maintenance

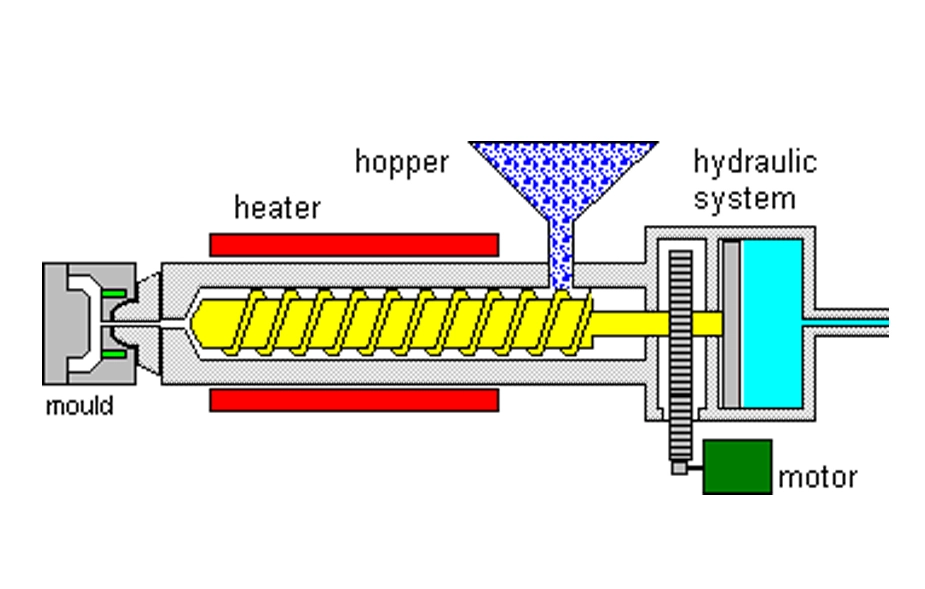

Material selection and preparation

Injection molding machine setup

Injection molding process (filling, packing, and cooling)

Part ejection and removal

Post-molding processes (trimming, finishing, and inspection)

Quality control measures

Repeat process for mass production

Email Us Directly

marketing@ywxmolding.com