YWX, a professional plastic prototyping company, supplies rapid prototype molding and babyplast molding services.

1. Small-batch injection molding with aluminum or soft steel molds is essential for quick mold completion. Using a stock of 200 various size of moldbase can speed up production.

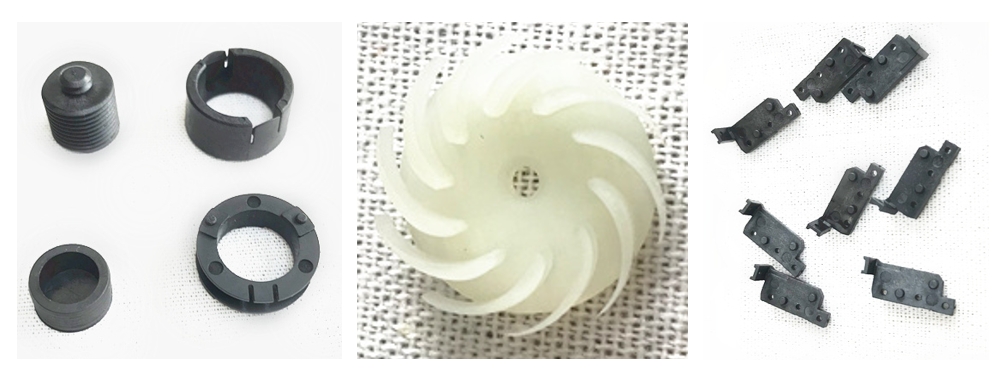

2. Babyplast molding technology eliminates the need for a mold base, enabling delivery of tiny, precise parts within 20 days, with dimension tolerance down to 0.01mm and weights as light as 0.02g.

Get prototype injection molded parts fast!

Plastic rapid prototyping allows for the quick production of prototypes, reducing the time required for product development and iteration.Usually 1-3 weeks, we will indicate the delivery time when providing your quotation.

Rapid prototyping with plastic materials is generally more cost-effective compared to traditional manufacturing methods, such as CNC machining or injection molding.

Plastic rapid prototyping offers design flexibility, allowing for the production of complex geometries, undercuts, and intricate details in prototypes.

Shot volume for our plastic rapid prototyping services ranged from 0.02 g to 1500g.

Typically <0.004″ (0.1 mm) for plastic rapid prototyping. Tolerance of 0.001″ (0.025 mm) is possible with certain materials and part geometry. Let’s discuss your application.

Plastic prototyping can be used for functional testing, allowing engineers to evaluate the performance and functionality of the product before moving to mass production.

Plastic prototyping provide a tangible representation of the product, making it easier to visualize and communicate design concepts to stakeholders, clients, or investors.

Plastic rapid prototyping allows for the customization of prototypes to meet specific design requirements or client preferences.

Rapid plastic prototyping helps mitigate the risk of costly errors or design flaws by allowing for early identification and resolution of issues before investing in mass production.

Plastic rapid prototyping enables the integration of features such as inserts, threads, or other functional elements directly into the prototype, providing a more realistic representation of the final product.

Plastic prototyping can be used for quality control purposes, allowing for the evaluation of dimensional accuracy, surface finish, and other critical aspects of the product.

Plastic rapid prototyping eliminates the need for expensive tooling or molds required in traditional manufacturing methods, saving time and resources during the prototyping stage.

Plastic rapid prototyping can be easily scaled up or down to meet different prototyping needs, from low-volume to high-volume production.

Plastic prototyping facilitate collaboration and feedback from various stakeholders, including designers, engineers, and end-users, leading to improved product development and customer satisfaction.

YWX maintains a stock of over 200 sets of mold bases in various sizes, which eliminates the need for purchasing new mold bases. We utilize soft steel or aluminum for the molds, which do not require hardening, thereby streamlining the procurement and processing phases. As a result, we, as a dedicated plastic prototype service supplier, can typically deliver samples within 1 to 3 weeks for standard products.

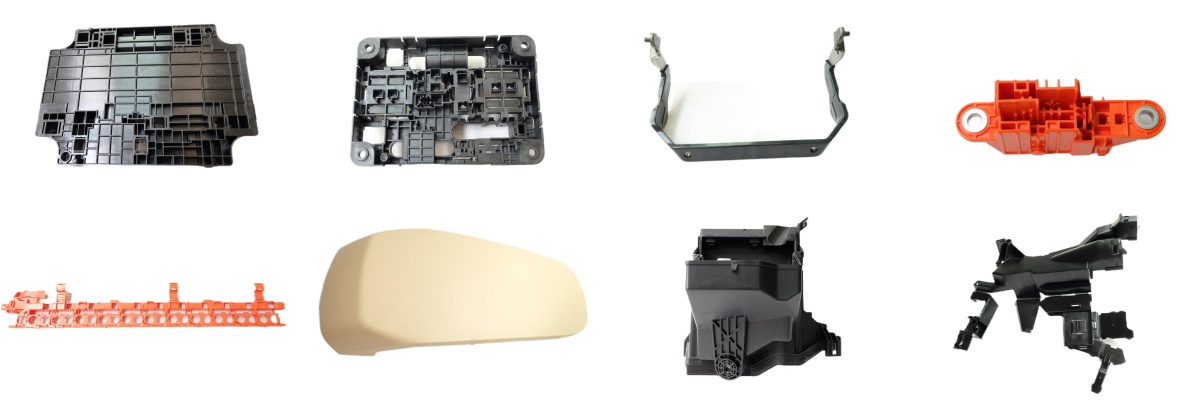

Yes, we certainly can! We often create intricate products for our clients within tight deadlines, including items like connectors (over-molding), dual-color automotive lights, and cable trays. Our state-of-the-art processing equipment and injection molding machines, which range from 10T to 1650T, enable us to guarantee high efficiency and quality in our work.

Prototype molding differs from production molding in that, due to lower production volumes, we utilize manual inserts rather than automated processes. The cooling may also be less efficient, leading to longer molding cycles and higher unit costs. However, this approach significantly reduces both the expenses and timeline associated with mold development.

YWX Molding can manufacture parts weighing as little as 0.02g and up to 1500g. Our standard dimensional tolerance is typically under 0.004″ (0.1 mm), and with specific materials and geometries, we can achieve tolerances as tight as 0.001″ (0.025 mm). Feel free to reach out to discuss your specific application.

Certainly! YWX Molding provides a range of services, including silk screening, laser welding, printing, and assembly.