Transforming Ideas into Reality

YWX is a premier China rapid prototyping supplier that supplies custom rapid prototyping, rapid tooling, and advanced manufacturing services like CNC machining and 3D printing. Whether you need low-volume rapid prototype molding or high-precision parts, our rapid prototyping factory accelerates your product development cycle, enabling fast design validation and refinement. Global innovators consistently choose YWX for their China rapid prototype needs because our proven track record establishes us as a reliable China rapid prototype partner for complex international projects. Partner with YWX Molding to turn concepts into high-quality prototypes efficiently.

At YWX Molding, we stand out among chinese prototype manufacturers because we know Custom rapid prototyping plays a crucial role in numerous industries by enabling fast product development, testing, and iteration. With rapid prototyping services, your business can reduce production time, minimize costs, and enhance product innovation. Below are some key application areas where rapid prototyping and manufacturing bring significant benefits, highlighting the versatility offered by top chinese prototype manufacturers.

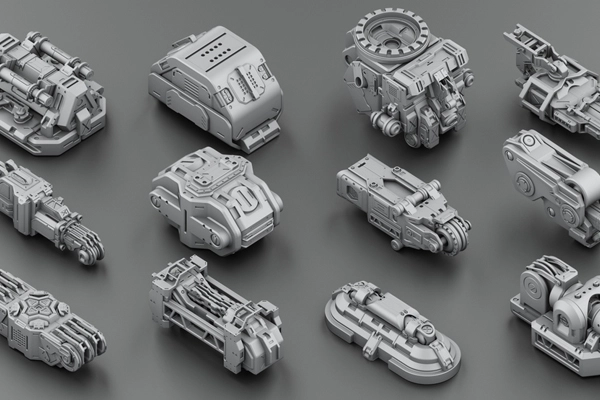

Automotive Industry: Automotive manufacturers is able to rapid injection molding prototypes to develop durable and lightweight car parts.

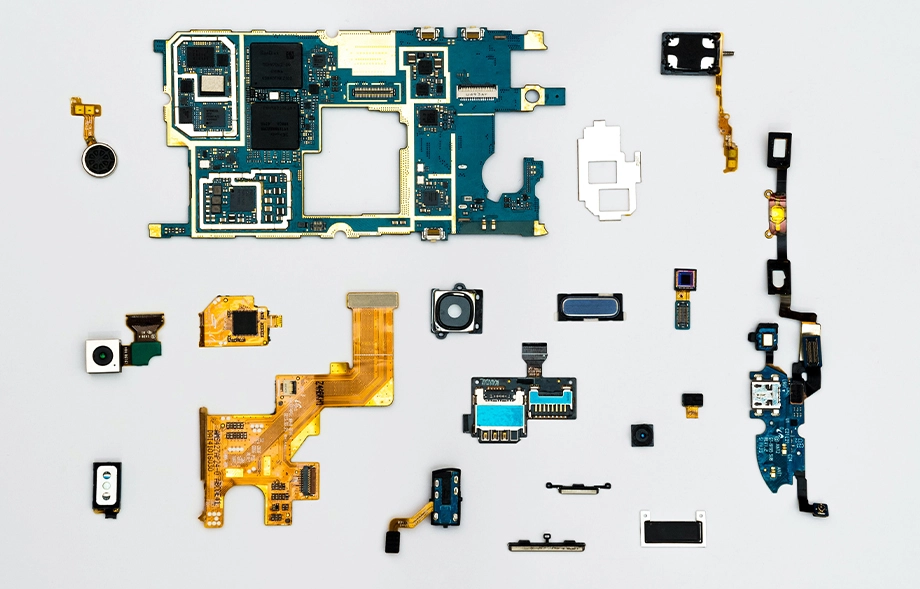

Consumer Electronics: Engineers enable fast prototyping service for ergonomic and compact device enclosures.

Healthcare & Medical Devices: YWX supports rapid prototyping and tooling to develop precise surgical instruments.

Industrial Manufacturing: Factory engineers can apply rapid machining and fabrication techniques to develop efficient industrial components.

From rapid prototyping innovation in the automotive industry to custom rapid prototyping in healthcare, the applications of rapid prototyping and rapid manufacturing are vast. By leveraging prototyping and manufacturing, businesses can enhance efficiency, reduce time to market, and improve product performance.

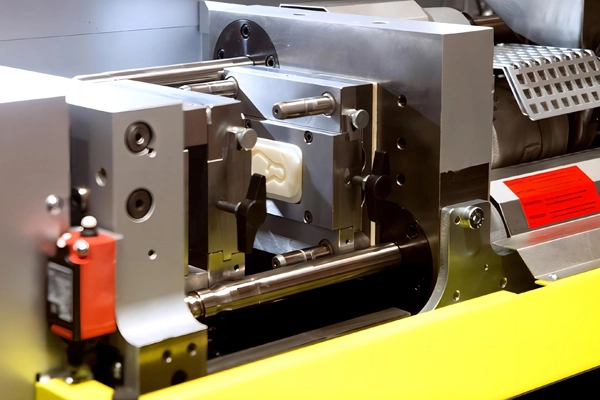

Rapid prototyping is a manufacturing process that swiftly creates physical models of designs using techniques like 3D printing and CNC machining. This approach allows designers and engineers to quickly test and refine product concepts before committing to full-scale production.

Key Steps in Rapid Prototyping:

Design Creation: Engineers develop a digital model of the product using Computer-Aided Design (CAD) software.

Prototype Fabrication: The digital design is transformed into a physical prototype through methods such as 3D printing, CNC machining, or injection molding.

Evaluation and Refinement: The rapid prototype undergoes testing to assess aspects like functionality, ergonomics, and aesthetics. Feedback from these tests informs necessary design adjustments.

Iteration: The Rapid prototyping process repeats as needed, with each iteration bringing the design closer to the final product specifications.

Rapid prototyping is a game-changer for product design and manufacturing, offering speed, flexibility, and cost savings. By facilitating early-stage testing and refinement, prototyping manufacturing helps companies minimize errors and maximize efficiency. As technology advances, rapid prototyping will continue to shape the future of industrial production and innovation.

Rapid prototyping is experiencing several trends and innovations that are shaping the industry. Here are some key points:

1. Rapid Prototyping: The adoption of rapid prototyping techniques, such as 3D printing and digital prototyping, allows for faster and more cost-effective development cycles.

2. Iterative Design: Rapid prototyping is being used to facilitate iterative design processes, enabling designers to quickly test and refine their ideas.

3. Collaborative Prototyping: Rapid prototyping tools and technologies that support collaborative prototyping, such as online platforms and virtual reality, are gaining popularity.

4. Integration of IoT and Electronics: Rapid Prototyping is now incorporating the integration of Internet of Things (IoT) devices and electronics, enabling the development of smart and connected products.

5. Material Innovations: New materials, such as biodegradable and flexible materials, are being introduced in rapid prototyping, expanding the possibilities for product development.

These trends and innovations are driving advancements in rapid prototyping, making it an essential tool for idea development and innovation in various industries.

Email Us Directly

marketing@ywxmolding.com